10 o’clock start on the first day. The bike shop is closed on a Monday so it was just Rob & me. We spent the morning having a chat and sizing me up for the frame. We ended up with a size fairly close to my existing bike but a fair bit shorter reach for a sporty ride. These measurements were transferred to BikeCad to get the tube measurements and print off the design as a plan.

Down to the workshop for a bit of health and safety and some practice brazing. It’s not hugely different to soldering but just a much higher temperature. We were using propane and oxygen with an in-line gas fluxer. Propane first, producing a yellow flame about a foot long and very feathered and smokey at the end; add the oxygen and it goes green from the flux (would be blue). We were aiming for a flame about a foot long with a small cone about an inch long at the tip of the torch. This is where the heat is. Heat the tube to a dull red / cherry colour and then add the brass rod. I had a very shaky hand holding the brass. Keep the flame moving and the brass stationary.

My tubes were here on the beach.

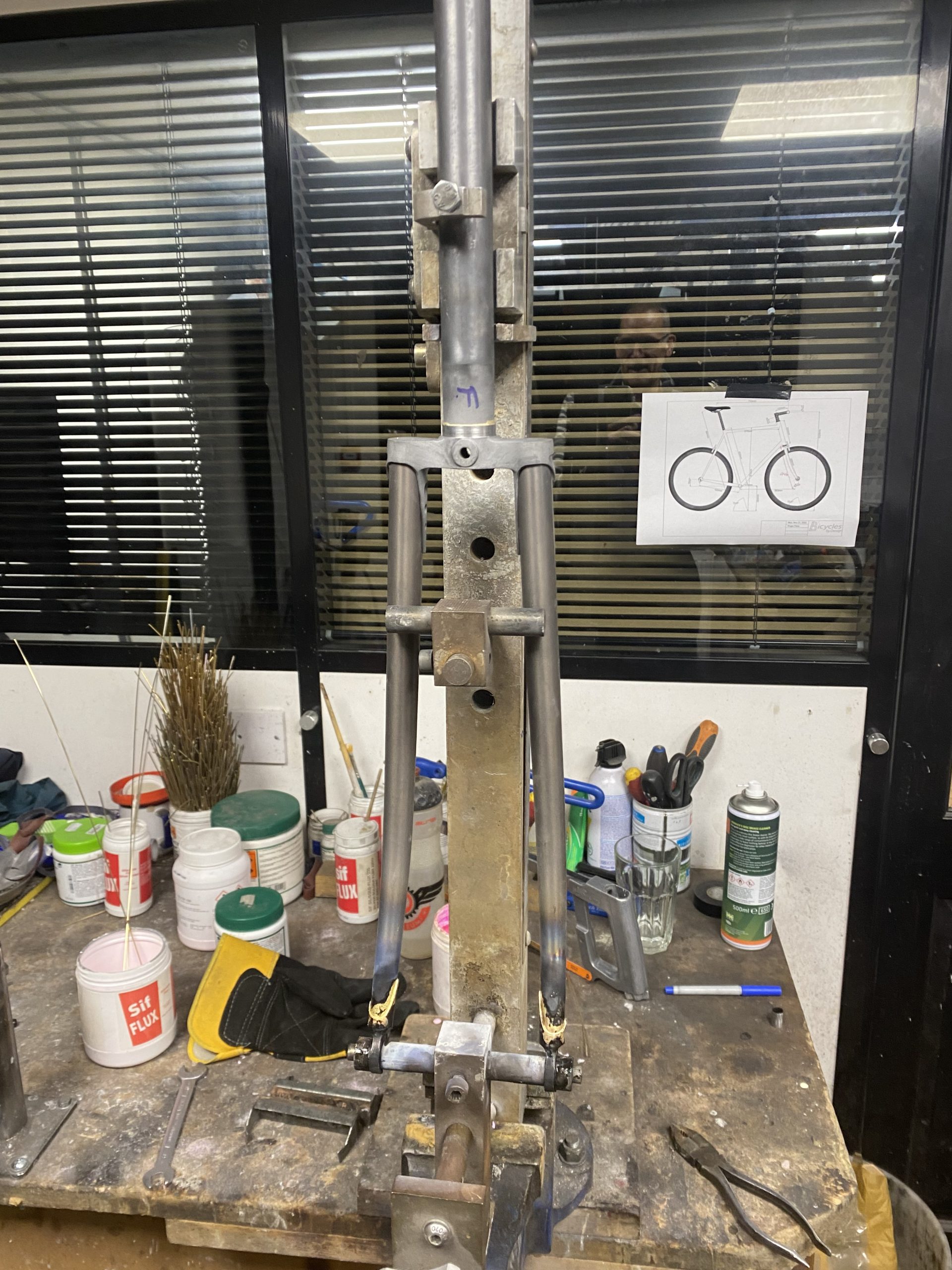

The first joint was fitting the fork crown to the steerer as they are both thick pieces of metal so need a lot of heat and are difficult to get too wrong. A clean up with the sand blaster first for a nice clean joint. Heat the lug and make sure the tube is also up to heat and work around with the brass. Once the brass from your last bit starts to go fluid again, add a bit more to continue the braze all the way around the lug. You can see the brass flow around and through the joint, following the heat. They look pretty rough after with a lot of flux, blackening from the heat and brass spatter from my shaky hand. Joint was good though and looked much better after another sand blast. I filed the bottom of the steerer tube flush with the bottom of the fork crown so you can see the bottom of the fork crown, the ring of the steerer and the ring of brass braze between the two.

After lunch we set up various jigs to line up the dropouts in the tubes and brazed the rear dropouts. As they cooled I reamed the crown race seat and Rob cut the fork blades to size and ground out the front dropouts as the tolerance was a bit tight. Once the seat stays were cool, I sand blasted the rear dropouts and filed and emeryed around the sockets for the stays to tidy them up.

Then we brazed the front dropouts. I’m still a bit shakey on the brazing but I think I’m getting better but mainly using too much brass. Rob had to do a bit of a tidy on one of them.

Last job of the day was to cut down the head tube.

We’re on schedule I think.

Hammered down all day so a nice wet ride back to Ironbridge.