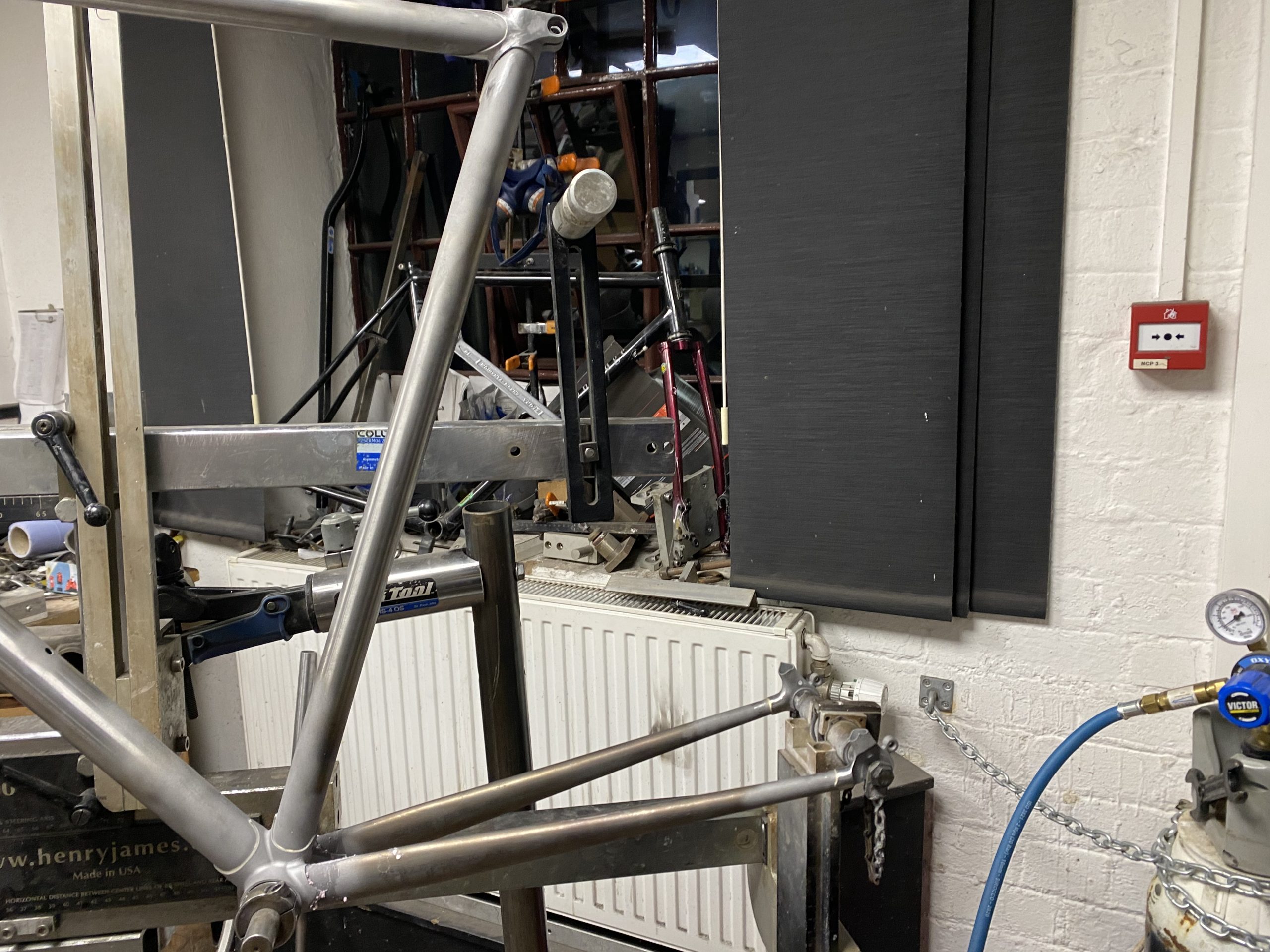

It’s beginning to look like a bike.

The first job was brazing the bottom bracket. Rob started off and I did some of it. Lots of heat to get the bottom bracket shell up to temperature then a fair bit of brass to flow into the joint and come out of the bottom. All the way around the tube joints then a second round to re-flow any big blobs of brass either into the joint or to somewhere where it’s easy to get rid of as it’s too difficult to file into the tight spaces. We then did the top and bottom head tube lugs and finally the seat lug. Some of the tangs needed tapping in.

The last job for the morning was cutting the fork blades to size and then brazing them into the fork crown. Again lots of heat to get the fork crown up to temperature.

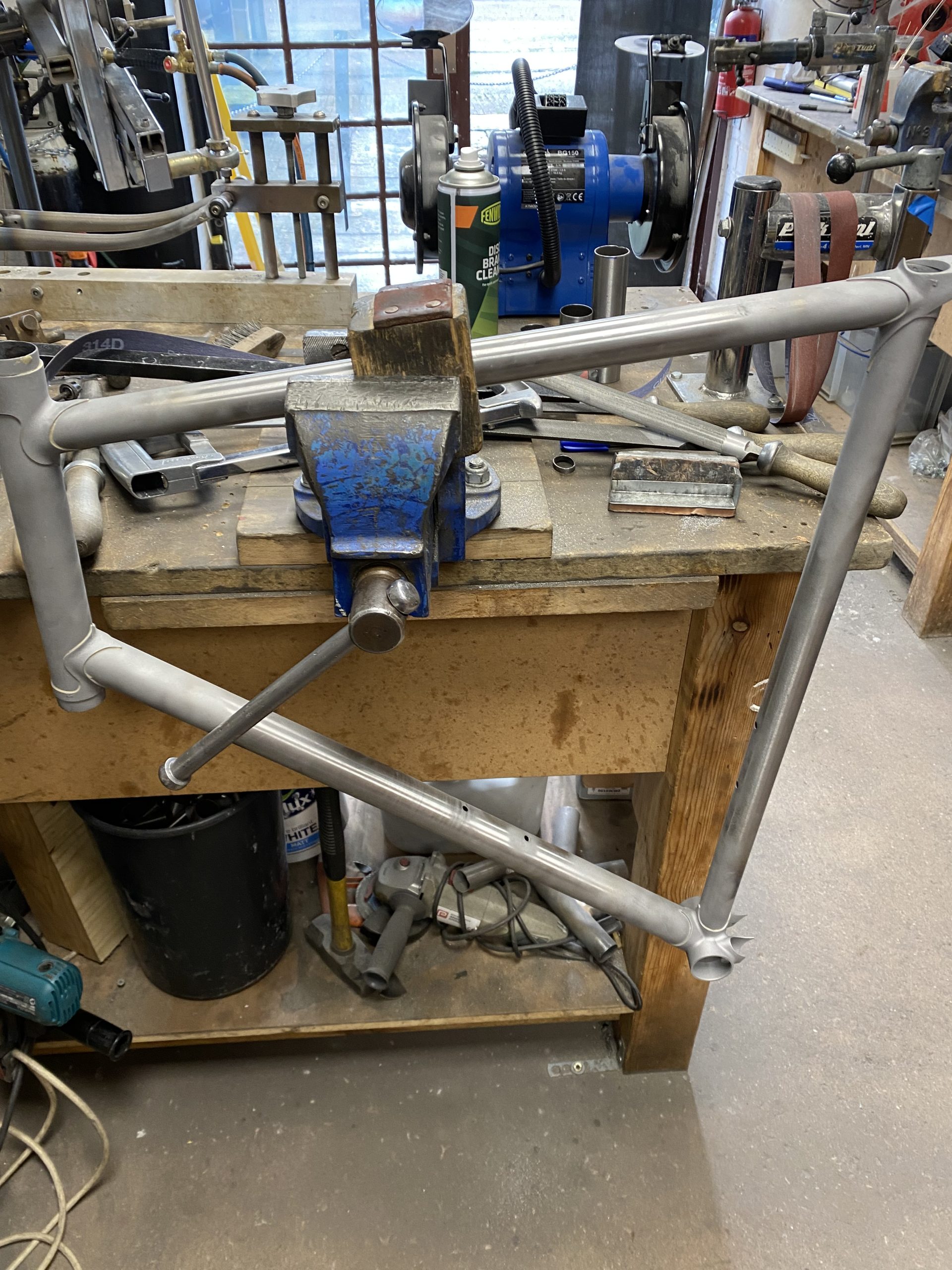

That took us up to lunch time. The first part of the afternoon was tidying up the main frame in the media blaster and followed by filing the lugs to remove any hammer marks from adjustment and to taper the tangs down to the frame tubes. I also removed the casting marks and generally tidied up. Finishing off with emery.

We put the frame back on the jig and measured for the chain stays. I cut them down about 20mm and then we could put them into the bottom bracket, track them and mark for mitres. I cut and filed the mitres and fluxed and prepped for brazing. We didn’t quite get to the brazing so I tidied up the forks instead.

The main frame and the forks ring with a lovely tone.

I cycled there and back over the Iron bridge and along the other side of the river for a change along the cycle path and canal.