We started off tidying the front dropouts by filing the dropouts and tapering the point down towards the fork blades. Then a polish with emery.

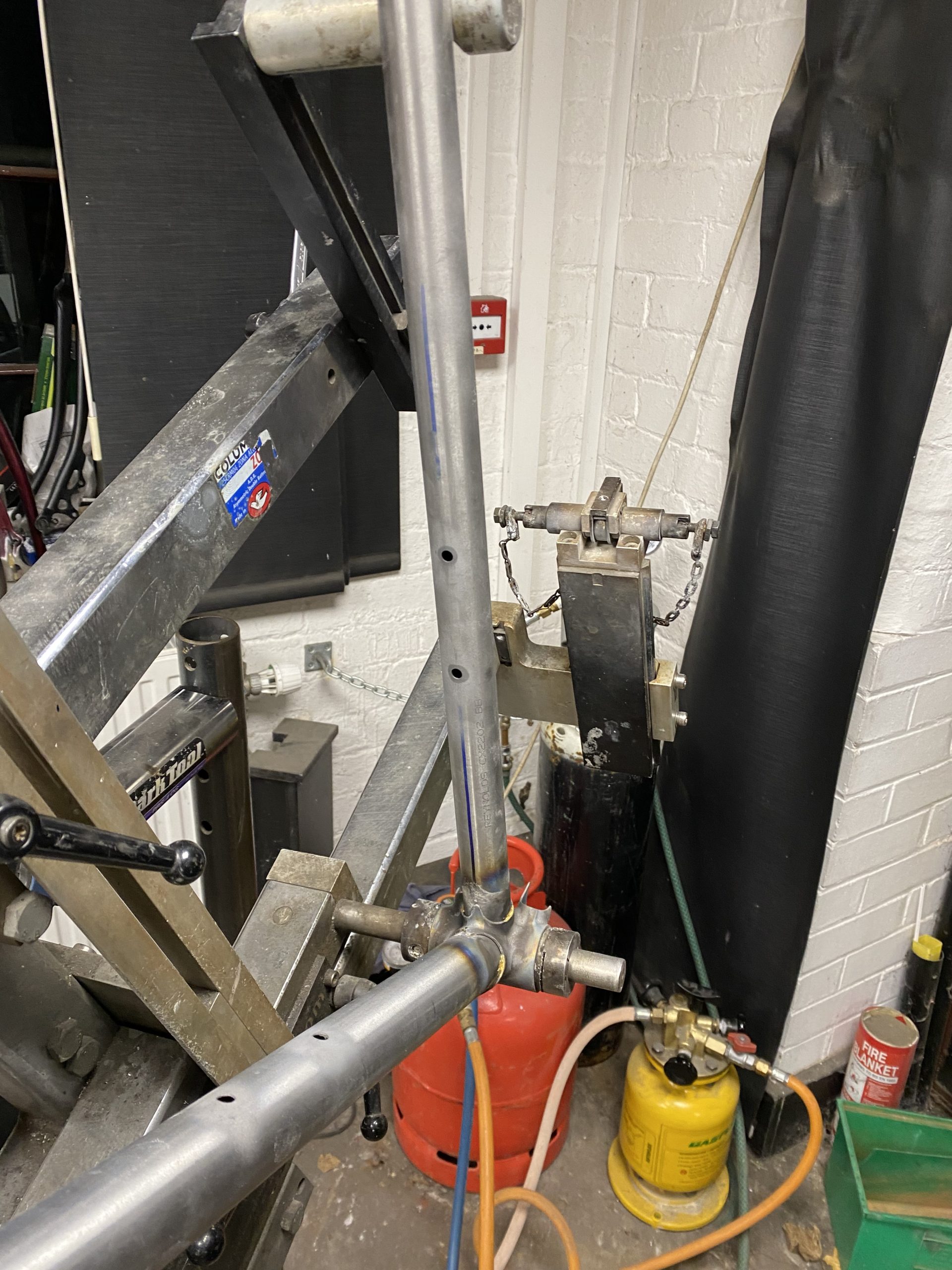

Then the hard stuff started. The head tube went into then jig to set the levels for the two head lugs, then we could start marking the mitres. BikeCad gives a printable mitre template for each tube so that was stuck around the tube as the starting point. I had to cut the mitres on all the main tubes so that the frame tubes for the front triangle all join neatly inside the lugs and are all the correct length. Starting with the down tube into the bottom bracket then the down tube to head tube; seat tube to bottom bracket; top tube to head tube and lastly the top tube to seat tube. the top tube was cut a bit long so that it could bet fettled to the correct length while getting the mitres right. Lots of cutting and filing and offering up and filing and checking and filing and checking again.

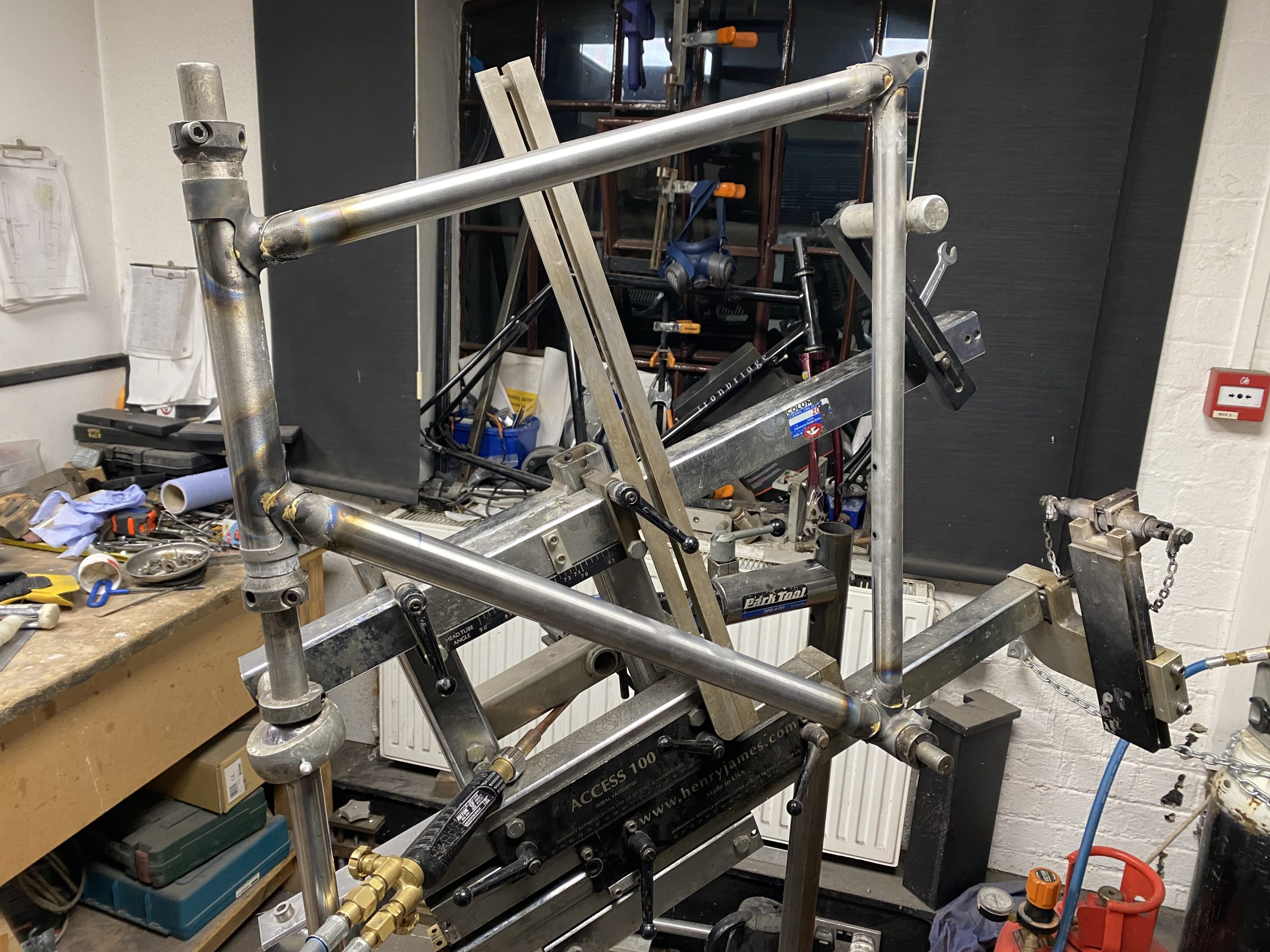

All mitres were cut and tidied up and then the seat tube cut to length. Everything was the taken off the jig. The bottle bosses were drilled and a breather hole in the top of the seat tube. The ends of the tubes were then sand blasted, fluxed and reassembled off the jig in the lugs. The frame then went back on the jig to make sure everything was lined up correctly and tacked each side of each lug. At this point we also heated the head tube lugs to reshape them a little to match the sloping top tube angles. We did not use the Llewellen lugs like I assumed.

The day ended with a front triangle checked for tracking on the bench by taking reference points along the down and seat tubes relative to the planes of the outer edges of the bottom bracket shell. It was about 4mm out but easy to nudge back. It’s now ready for brazing and it’s beginning to look like a bike frame.

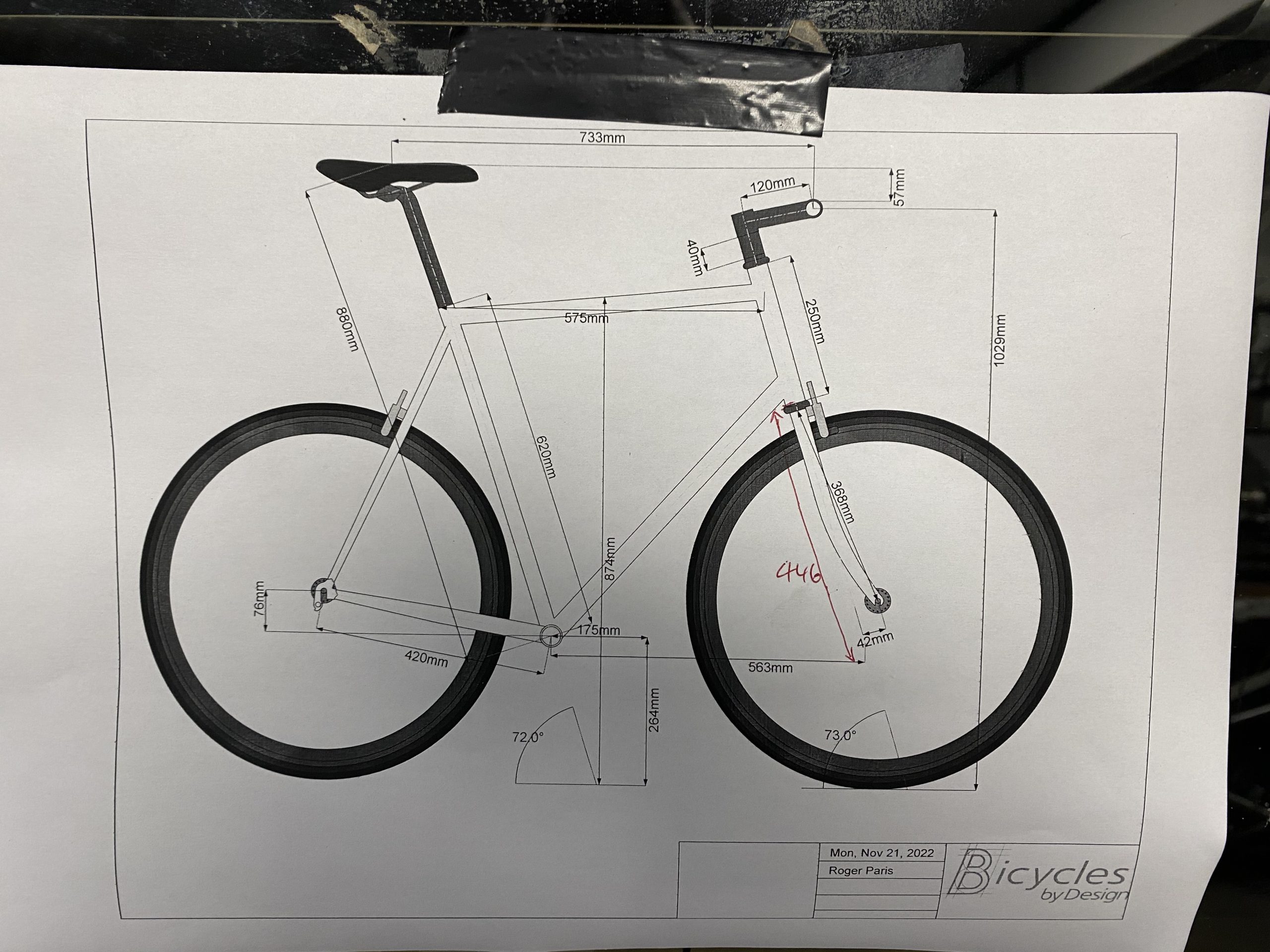

the design from BikeCad

front dropout point tapered to the fork blade

starting the first mitres on the bottom of the seat tube

seat and head tube in the jig

head tube to down tube

bottom of down tube

head tube to top tube

drilling for bottle bosses

front triangle assembled and tacked

It was a cold ride back but a dry day and a very pleasant commute.

That is beginning to look like a bike frame. We’ll done

even more so today